Luxury Vinyl Tiles (LVT): Complete Installation Guide for Flawless Finish

Core Requirements

LVT installations demand careful attention to detail according to BS 8203:2017:

- Sound subfloor preparation

- Proper moisture management

- Appropriate product selection

- Professional installation techniques

- Quality finishing procedures

Installation Process

Subfloor Preparation

- Mechanical removal of laitance

- Elimination of surface contaminants

- Thorough soundness check

- Smoothness assessment

- Basic preparation principles

- British Standards compliance

Moisture Management

- Mandatory moisture testing

- Calibrated hygrometer use

- RH level assessment (max 75%)

- Waterproof membrane application:

- Single coat for up to 98% RH

- Three-hour cure time

- Complete moisture isolation

- Prevention of floor failure

Key Components

Priming Solutions

- Essential surface preparation

- Optimized compound performance

- Absorbent subfloor treatment

- Time-saving options available

- Specialized applications:

- General-purpose primers

- Non-absorbent surface primers

- Calcium sulphate screed primers

Smoothing Compounds

- Perfect level surface creation

- Visual appearance assurance

- Heavy-duty options available:

- High compressive strength

- Excellent self-smoothing

- Heavy load capability

- High traffic tolerance

Flexible Solutions

- Plywood subfloor applications

- Steel surface installations

- Movement accommodation

- Crack prevention measures

- Appearance preservation

Technical Specifications

| Feature | Requirement | |---------|-------------| | RH Level Limit | 75% standard, 98% with membrane | | Cure Time | 3 hours for membrane | | Coverage | Varies by product | | Standards | BS 8203:2017 compliant | | Surface Types | Concrete, plywood, steel | | Traffic Rating | Heavy-duty available |

Installation Techniques

Adhesive Application

- Pressure-sensitive solutions

- Instant grab properties

- Pattern creation capability

- Proper roller techniques:

- Paint roller application

- Ridge flattening

- Trowel mark prevention

- Visual appearance protection

Quality Control

- Compatibility verification

- Manufacturer guidelines

- RAG consultation

- Over 5,000 floorcoverings

- 200+ manufacturer coverage

Common Challenges

Moisture Issues

- Leading cause of floor failure

- Residual construction moisture

- Rising damp problems

- Adhesive degradation

- Surface blistering

- Installation lifting

Prevention Measures

- Proper moisture testing

- Appropriate membrane use

- Correct primer selection

- Quality compound application

- Professional installation

Best Practices

Professional Requirements

- Standard compliance

- Proper tool selection

- Correct product application

- Quality control measures

- Regular assessment

Material Selection

- Appropriate primer choice

- Suitable compound selection

- Compatible adhesive use

- Quality control checks

- Manufacturer guidance

Long-term Benefits

Performance Advantages

- Extended installation life

- Maintained appearance

- Structural integrity

- Traffic resistance

- Load bearing capacity

Cost Efficiency

- Reduced maintenance

- Prevented callbacks

- Minimized repairs

- Extended longevity

- Customer satisfaction

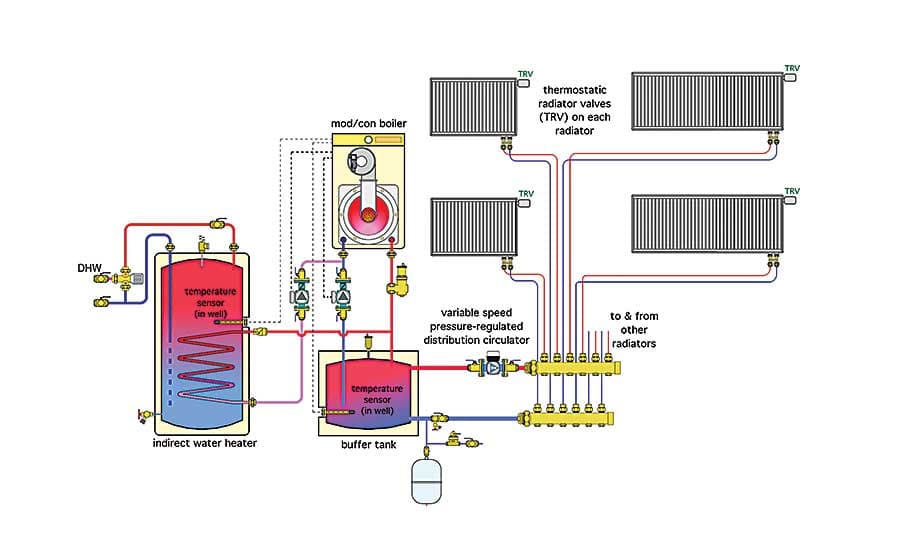

Hydronic Heating: A Solution for Net Zero Buildings

Explore how hydronic-based heating systems provide efficient solutions for net zero buildings while maintaining superior comfort levels.

Future Homes Standard 2025: Transforming Roofing and Insulation

Explore how the Future Homes Standard 2025 is revolutionizing residential construction with new requirements for sustainable roofing and insulation solutions.

Hardie® Architectural Panel: Innovative Solution for Modular Construction

Discover how Beam Contracting utilized Hardie® Architectural Panel for their innovative modular flats project in Poole, delivering fire safety and sustainability benefits.